How to extend the service life of the laminating machine

How to extend the life of the laminating machine:

1. There may be problems such as damage to electrical components or wire ends during transportation. Before use, it should be strictly checked to ensure the personal safety of the staff. It is necessary to connect the bottom line after the switch is completed. After the inspection is completed, the power can be turned on and attention is paid to whether there is leakage.

2. When installing, pay attention to adjusting the vertical and horizontal center line of the extruder, and it must not deviate or skew from the center of the traction roller.

3. When the winding is gradually increased, due to the diameter of the winding, the demand for the cooperative traction speed and the winding speed are required.

4, should pay close attention to the operation of the main machine of the laminating machine, timely adjust and modify the electrical instruments, controllers, etc., to ensure the normal operation of the equipment.

5. Generally, it is necessary to replace the lubricating oil of the main engine, gear box and traction reducer in about ten days to ensure the normal operation of the equipment, avoid damage and overheating of the machine. Also check to see if the joint is tight and avoid loose screws.

6. The compressed air pipe should be kept moderate, and the leakage of compressed air should be avoided during the traction process.

7. Organize and replace the head of the filter in time to prevent the particle mixture from damaging the screw cylinder.

8, preheating time is not suitable for the process, to avoid material blockage.

Article from: Laminating machine www.jmkaisheng.com

-

08-15

Working principle of laminating machine

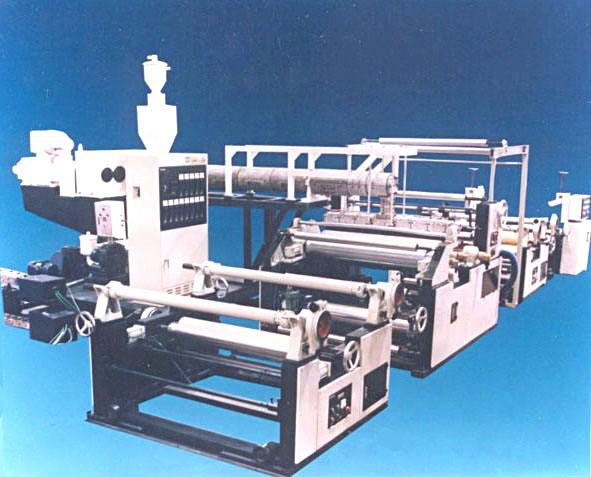

The laminating machine is mainly composed of four types of machines, namely the main machine, the mirror roll system, the discharging system and the winding system. Our company's laminating machin

-

08-15

Laminating machine faulty treatment method

In some cases, because of the improper use of our methods, we often have problems, especially when using the laminating machine, which causes great troubles for the operation. Therefore, we must grasp

-

08-15

Laminating machine die cleaning method

Some parts of the machine, or some parts, need to be cleaned regularly, so that it will prolong its life, and it can clean the dust regularly, so that it will not malfunction when it is operated. Is o

-

08-15

Laminating machine failure processing method

Heating system(1) Slow heating: The yellow light of the temperature control table (OUT1) is on. Please check the index of the current meter above. If the index is not possible, the block is burnt out